| By demonstrating the severity potential of these hazards we believe that organisations can: |

- re-test existing management controls for focus, completeness and robustness

- re-affirm that work as imagined in procedures designed to address these essential risks actually translates into work as done on the ground

- engage with workforces and other stakeholders to seek well-managed, cooperative change and innovation

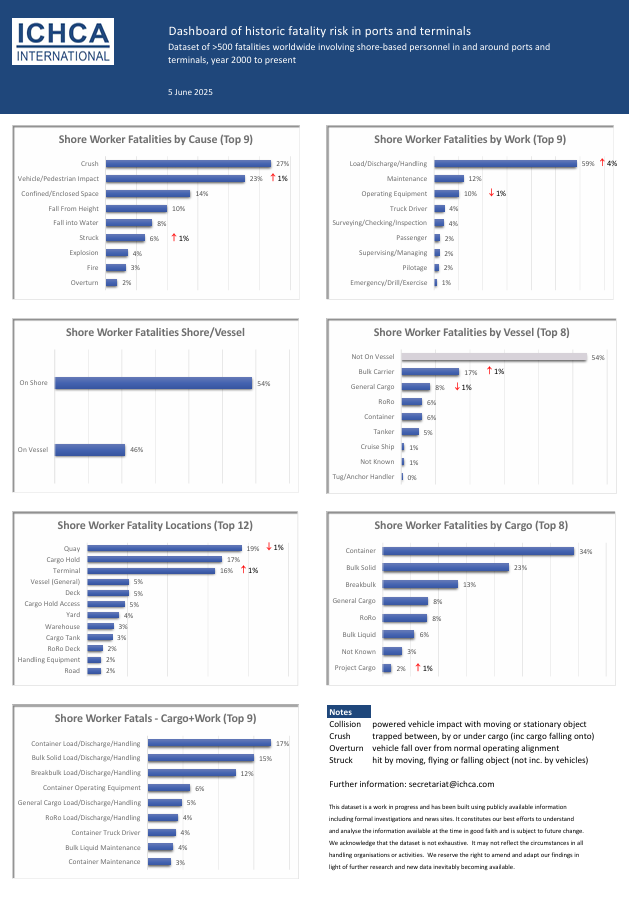

| The dataset covers over 500 fatalities involving port workers, contractors, visitors and other third parties from 2000 to June 2025. |

| What the dashboard is telling us |

- Crush by cargo is the leading historic cause of fatalities worldwide in our industry – over a quarter of all incidents in the dataset

| This includes being trapped by, between or under cargo. It is typically the result of cargo falling, moving, turning, slewing or otherwise being displaced as a result of lifting failure, impacts, other forces or loss of stability. Controls that ensure people are never, ever under a suspended load or under the travel path remain absolutely essential and the ‘first principle’ of cargo operations. Control of means of access so that people are never in a position where they can be engulfed in, or vulnerable to, moving cargo should always be in place with lifting operations competently planned and managed. |

- Pedestrians run over by vehicles, particularly by handling equipment is the (close) second highest fatal incidence.

| The only soft things found in ports and terminals are human beings. Effective segregation of people and vehicles is a safety bedrock. All ports and terminals should use the triple lock of Safe Site (design and activity), Safe Vehicle and Safe Driver. |

- Fall is the third highest instance for shore based workers.

| The dashboard separates fall from height and fall into water to provide slightly more granular information. But in either case work anywhere that, if there were no precautions in place, a person could fall a distance liable to cause personal injury should be properly planned, supervised and carried out by competent people with the skills, knowledge and experience to do the job. Use the right type of equipment for working at height. Check that measures designed to prevent falls are in place, in a condition that will do the job and are used. Avoid work at height where it’s reasonably practicable to do so. Where work at height cannot be easily avoided, prevent falls using either an existing place of work that is already safe or the right type of equipment. Where the risk cannot be eliminated, minimise the distance and consequences of a fall by using the right type of equipment. |

- Confined/Enclosed Space also stands out as a key hazard.

| There are different definitions of a confined space and it even has different names – an Enclosed Space in maritime. Whatever the name or definition, the hazard is serious. The most repeated cause of fatality here, is too little oxygen though sometimes toxic gases may be involved. Entry by mistake or ‘just to quickly get/do something’ occur several times in the dataset. As with falls, the hierarchy of controls is essential. Nobody should enter a potentially confined space if there is an alternative. If it is essential to enter, organisations should make sure that people know what to do and have the means to do it safely. Where practicable, potentially confined/enclosed spaces should be secured against unplanned/uncontrolled entry. |

| In all the above, good safety leadership can make a real difference. Telling people to work a particular way is not enough to create reliable and lasting hazard control, supporting them to do it the safe way is critical. |

- Loading/discharge and handling account for over half the instances in the dataset.

| This aligns with the hazards listed above, but still needs further analysis and more granular understanding. We have been able to select out some specific areas includingMaintenance (explosion, crush, fall from height) Operating Handling Equipment (fall into water and overturn), visiting Haulage (vehicle / pedestrian impact and crush) and activity around Surveying, Checking and Inspection (confined / enclosed space, vehicle / pedestrian impact and crush). |

| In this edition of the dashboard a further graph has been included to identify the cargo type with the work activity. This shows that loading/discharge/handling of Containers gives the highest risk of fatality followed closely by Bulk Solid and Breakbulk. The fourth highest risk historically has been associated with operating container handling equipment. There is a reasonable argument that this category should be included in loading/discharge/handling of Containers. It is separated out here because the available information allows us to do so for greater detail. However, the reader may choose to combine the two in their own analysis. |

- Almost even split between shore and onboard vessel for key hazard locations

- Bulk Carriers were the vessel type most likely to give rise to on-board fatalities, followed by General Cargo, RoRo, Container and Tankers in absolute numbers.Bulk Carriers, RoRo and Container Vessels appeared to show more incidents proportionately than their share of the world’s fleet.

- The highest instances On Shore were located on the Quay, wider Terminal, Yards and Warehouses. On Vessels the highest instances were Cargo Holds/Tanks, Cargo Hold Access and working Decks.

- Considering different cargo types, in a simple mathematical count, the largest number of fatalities were associated with Containers, followed by Bulk Solid, then Breakbulk, General Cargo and RoRo.

| The dashboard is available in the members area and will be updated periodically to go to the dedicated dashboard page follow the link below: |

|