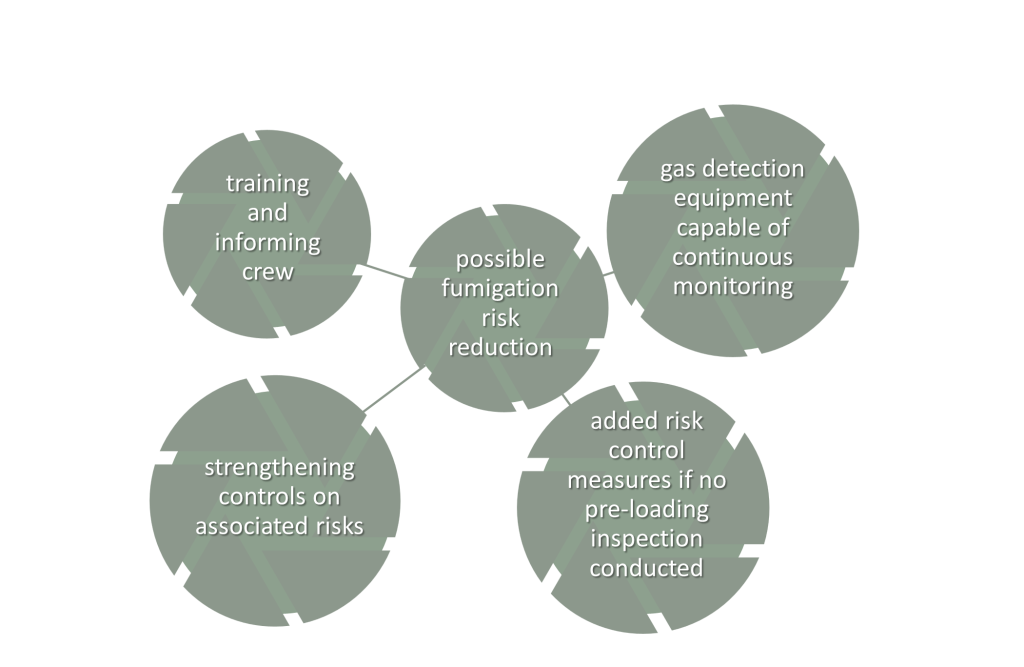

| None of the casualty investigation reports found that the holds were tested for gas tightness prior to loading. The proposal is that where the fumigator-in-charge cannot determine that the cargo can be made sufficiently gastight, there should be further controls on all spaces where people are at risk e.g. additional, continuous, gas monitoring. |

| In some cases, crews were not sufficiently aware of the risks of carrying fumigated cargo, including exposure symptoms and appropriate actions. The paper suggests making the fumigator-in-charge responsible for briefing the crew directly to help standardise training by the person most qualified to deliver it. This briefing should include an understanding that fumigant may be present in the cargo and/or trapped in the hold even after the cargo is discharged. |

| Finally, the paper notes that ‘fumigation hazards are not limited to exposure to the toxic gas’. Fumigated cargoes may be oxygen depleting. There is also a fire or explosion risk throughout the voyage. Phosphine is flammable, highly reactive and prone to self-ignition in relatively low concentrations. Over-pressurization can lead to explosion in the early fumigation stages. So application of the fumigant needs to be carefully planned to avoid over-pressurisation and avoid ignition. |

|