Video: The Hidden Risks of Sling Damage and Misuse

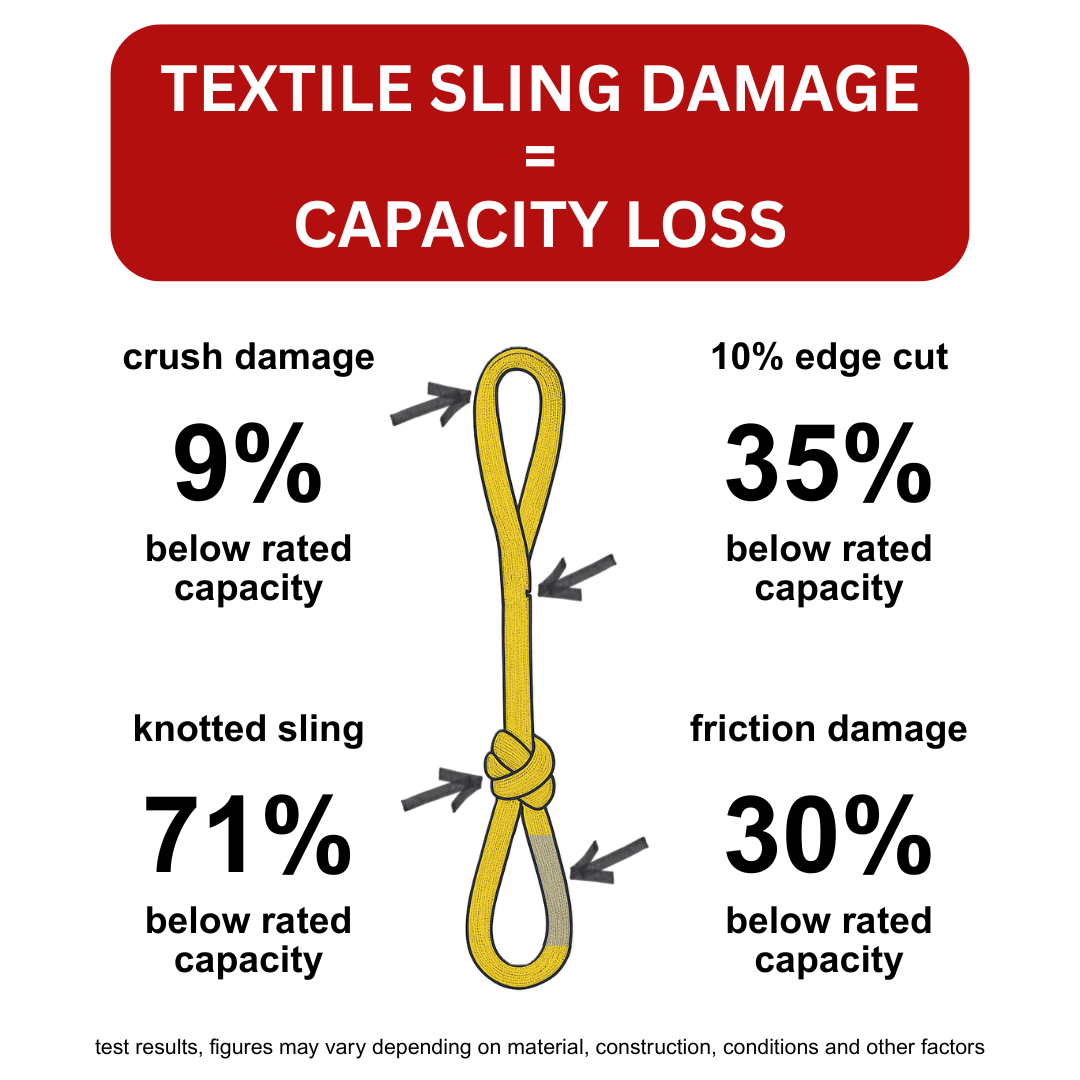

Textile slings are widely used in cargo handling, but even small amounts of damage or incorrect use can significantly reduce their strength in the worst case – by more than 70%.

ICHCA member Checkmate, and Prodragon both working in Association with G2Ocean have produced a 6-minute video showing real testbed results of sling failures under different conditions. The video highlights how poor inspection routines or improper use can leave defective slings in service, exposing workers and operations to serious risks.

What the video shows

Through controlled tests, slings with different types of damage and misuse were pull-tested to destruction. All slings were identical: polyester webbing, 50mm wide, 2.5m long, eye-to-eye simplex construction.

The results are striking:

| Test | Damage/misuse | Failure below rated capacity |

| 1 | 10% edge cut | failed 35% below rated capacity |

| 2 | 20% edge cut | failed 56% below rated capacity |

| 3 | 10% centre cut | failed 30% below rated capacity |

| 4 | longitudinal cut | failed 6% below rated capacity |

| 5 | hook piercing | failed 4% below rated capacity |

| 6 | surface abrasion | failed 1% below rated capacity |

| 7 | friction damage | failed 30% below rated capacity |

| 8 | crushing damage | failed 9% below rated capacity |

| 9 | knotted sling | failed 71% below rated capacity |

| 10 | excessive hook diameter | failed 1% below rated capacity |

| 11 | slings joined together | failed 36% below rated capacity |

Watch the video

The video shows each sling failure at normal speed and in slow motion. It’s a powerful reminder that inspection, training, and correct sling use are critical to preventing incidents.

Acknowledgement

ICHCA thanks Checkmate and Prodragon in Association with G2Ocean for making this valuable video freely available.