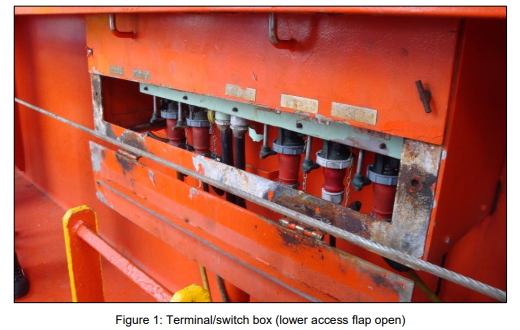

Safety Alert: Health hazard to a dock worker due to electric shock when connecting a refrigerated container on board a container ship

A dock worker connecting a deck stowed refrigerated container to the ship’s power supply received an electric shock when inserting the plug. Thankfully he was able to leave the scene under his own power and report what had happened.

Why it happened

• the switch box housing rubber seal was damaged and insufficiently prevented moisture ingress, leading to a so-called creepage distance formation in the housing, which could trigger a fault current

• the earthing connection was severely impaired due to corrosion and/or loose contact

• the fault current caused by the creepage distance was therefore not (exclusively) discharged directly via the PE conductor in the direction of the ship’s hull. Instead, it flowed partially through the body of the dock worker during contact with the switch box housing.

Random checks on board the ship revealed that other terminal/switch boxes had similar defects. In the course of the investigation, dock worker shock incidents involving five other vessels were identified. BSU therefore assumed that “dangerous incidents frequently occur in ports around the world in connection with the connection of reefer containers, but that these are not reported due to their mild outcome and are therefore not investigated in depth. This in turn is probably a decisive reason why the on-board inspection and maintenance of the relevant equipment, as well as its random inspection by classification societies and authorities, do not seem to have the importance they should have in relation to the serious dangers that can emanate from defective electrical equipment.”

Measures:

• Planning, implementation and documentation of regular inspections of the technical condition of all terminal/switch boxes for refrigerated containers by the relevant qualified technical personnel on board

• Inclusion of inspection routines in the ship’s maintenance system

• Immediate decommissioning of defective terminal/switch boxes until they have been professionally repaired

• Inspection of the terminal/switch boxes by a shore-based service company at fixed intervals

• Greater consideration of the (random) inspection of the technical condition of reefer container terminal/switch boxes when surveys are carried out by the classification societies and during Port State Controls

FOR THE FULL REPORT CLICK HERE

ICHCA International is committed to helping industry to learn lessons fast, learn them once and make sure that they stay learnt. This information is intended to provide all organisations in the cargo supply chain with the opportunity to consider the events and to review and adapt their own health and safety control measures to proactively prevent future incidents.

We are grateful to the German Federal Bureau of Maritime Casualty Investigation for providing details and for raising awareness. We acknowledge their commitment to sharing learning to benefit others. If you have similar operations, please share this information with managers, operatives and any potentially affected third parties as appropriate. Please also review any of your relevant operations for similar hazardous conditions, risks, and controls. Learning content like this is highly valuable as it is based on real-world experience. We encourage everyone with publishable information about incidents to send it to us, so that we can raise awareness across the whole industry. Please contact us at secretariat@ichca.com sharing your insight could save a life or prevent injury.

For previous Safety Alerts follow the link: https://ichca.com/safety-alerts